|

|

Plaster & Gauze Rolls

Click to go directly to these topics: |

|

Data Sheets for Plasters

Data Sheets give mixing, best use, technical, and storage information. Click on the images for a PDF to print. Hydrocal comes in White (USG6) and Yellow (USG12) with the only difference being the color addition, which is not pertinent for the technical information.

|

|

|

|

|

|

|

USG1

Pottery |

USG2 Molding |

USG3 Casting |

USG4

Dental |

USG6 & 12 Hydrocal |

USG7

Cerami-Cal |

USG11 Hydrostone |

Plaster

Plaster is one of the most flexible, versatile art materials made. Molds, sculpture, hobby crafts, medical and dental uses: plaster serves all these needs and more. We can help you determine which plaster is right for your intended application. All plaster is packaged in standard 50-pound bags. Other types of plaster and gypsum stone are available with minimum orders of 2,000-4,000 lbs.

USG1

Pottery #1

Produces a break-resistant, smooth wearing mold designed for slip casting and jiggering applications. Formulated to provide stronger, longer-lasting ceramic slip cast molds. The industry standard for sanitaryware and dinnerware casting |

| Mix Ratio: |

70:100 |

| Expansion |

0.21% |

| Crush PSI |

2400 |

| Set Time |

27-37 min |

|

USG2

Molding Plaster

Great for plaster bats. A good utility plaster when expansion, hardness and strength are not of great importance. |

| Mix Ratio: |

70:100 |

| Expansion |

0.20% |

| Crush PSI |

1700-2500 |

| Set Time |

14-24 min |

|

USG3

Casting Plaster

Great for casting plaques and figurines. This general use industrial plaster is formulated for greater strength and chip resistance than regular plaster. Working properties and set time similar to Hydrocal White.

|

| Mix Ratio: |

70:100 |

| Expansion |

0.20% |

| Crush PSI |

1700-2500 |

| Set Time |

14-24 min |

|

USG4

Dental Lab Plaster

A general dental application plaster with a set time between 5 to 15 minutes. |

| Mix Ratio: |

70:100 |

| Expansion |

0.20% |

| Crush PSI |

2000 |

| Set Time |

5-15 min |

|

USG6

Hydrocal White Plaster

Our most general use plaster cement, it can be carved or added to, possesses excellent plasticity for workability, and a gradual setting time. Also has higher expansion properties. |

| Mix Ratio: |

40-50:100 |

| Expansion |

0.42% |

| Crush PSI |

6000 |

| Set Time |

20-30 min |

|

USG7

Ceramical Gypsum Plaster

Designed for use in pressing clayware. Exceptional strength with consisten absorption. Store indoors. Shelf life 90 days. |

| Mix Ratio: |

33:100 |

| Expansion |

0.13% |

| Crush PSI |

6000 |

| Set Time |

18-23 min |

|

USG11

Hydrostone Plaster

Hydrostone is an extremely hard and strong plaster. Its very low viscosity allows for excellent detail reproduction. Primarily used for high-quality art, novelty and statuary castings. Available in a non-yellowing formulation. Moderate expansion properties.

|

| Mix Ratio: |

22-100 |

| Expansion |

0.20% |

| Crush PSI |

13,000 |

| Set Time |

15-25 min |

|

USG12

Hydrocal 105 Plaster

This yellow dental stone is very similar to Hydrocal White, but tinted for dental work. |

| Mix Ratio: |

40-50:100 |

| Expansion |

0.42% |

| Crush PSI |

6,000 |

| Set Time |

20-30 min |

|

Plaster Mixing Instructions

General Mixing instructions -

Your mixing container and equipment should be clean and free of all previous plaster mixing debris. Old plaster will cause your new mix to set irregularly and at a faster rate.

Water needs to be carefully and specifically measured. Water temperature is very important to your set time. Testing water is at 70°F - use a thermometer! Hotter water will speed up your set time, cooler water will slow and retard the set time.

Plaster mixes into water: sift your plaster into the pre-measured water, allow to slake for 30 seconds and mix time will be about 30 - 60 seconds. Plaster ages, it is hydroscopic. Older plaster may require less water.

Adjusting and checking your Georgia Pacific (GP) plaster against USG plaster:

Nothing will be exactly the same as we all know. Correctly adjusting and controlling your water will be the key to achieving the best match for your needs.

Field Test Procedure - You will need the following:

• Waxed or Plastic cup

• Wooden stir stick

• Thermometer

• Timer

• Straightened paperclip

Mix using 200 gram test amounts with the prescribed water for the given plaster at 70°F. Mix in your cup as directed. Set your timer. As soon as the slurry appreciably stiffens, begin inserting the extended paperclip. When considerable pressure from your index finger is required to reach the bottom of the cup, you will have your set time. Test absorption by allowing the test cup of plaster to set overnight. Weigh your slug of plaster. Cover with room temperature water and soak for an hour. Re-weigh your slug of plaster. The % difference in weight will be your absorption. If you are matching this to your USG version, you need to make a slug of each for control purposes. If your set time or absorptions are different, these will be adjustable with more or less water and the temperature of the water.

For USG1, USG2, USG3, USG4, and USG5:

| • Mix should be 1 part water to 1½ parts plaster (or 35 lbs water to 50 lbs plaster) |

| • Slowly add plaster in water. |

| • Allow to soak for 2 minutes. |

| • Mix 2 minutes to heavy creme density. |

For USG7:

| • Mix should be 16.5 pounds water to 50 pounds USG7. |

| • Sift plaster slowly and evenly into water |

| • Allow to soak for 2-5 minutes (less time for smaller batches). |

| • Mix 10 minutes with high-speed mixer. Pour within 2 minutes of mixing. |

For USG6 & USG12:

| • Mix should be 10 quarts water to 50 pounds USG6 or USG12.. |

| • Dump plaster in water. |

| • Allow to soak for 2 minutes. |

| • Mix 2 minutes to heavy creme density. |

For USG11:

| • Mix should be 5.5 pounds water to 50 pounds USG11. |

| • Slowly add plaster in water. |

| • Allow to soak for 2 minutes. |

| • Mix 2 minutes to heavy creme density. Longer mixing = stronger mold & shorter set |

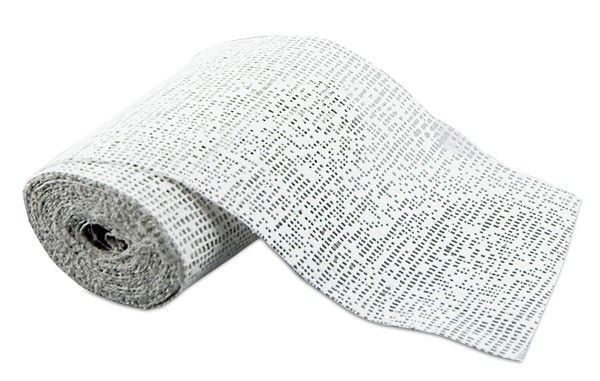

Plaster Gauze Rolls

|

Plaster Gauze • 50081K

For masks, mold backing, foundations and parts of sculptures; there is no end to the hundreds of uses for this versitile tape. Each box contains one roll that is 4" wide by 15' long. |

1-11 rolls |

12-31 rolls |

32+ rolls |

|

|

|

|

|

Mold Soap

|

| A soapy separating agent used to release plaster or other materials from plaster. We recommend applying a coat, wiping it off, blotting with a tissue or soft cloth, and then repeating for a second coat. Sold in pints only. |

|

|

|